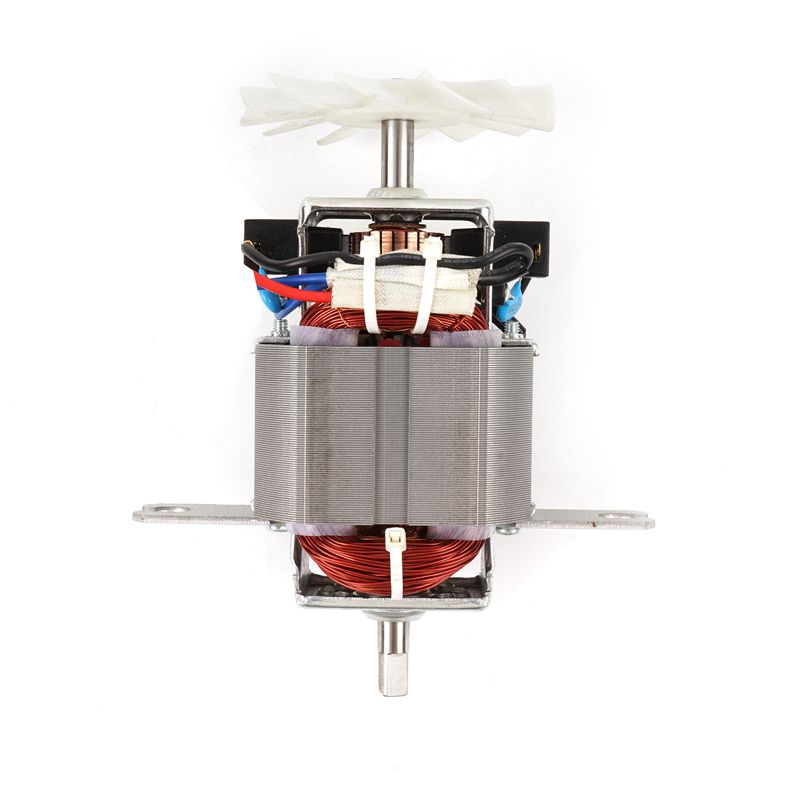

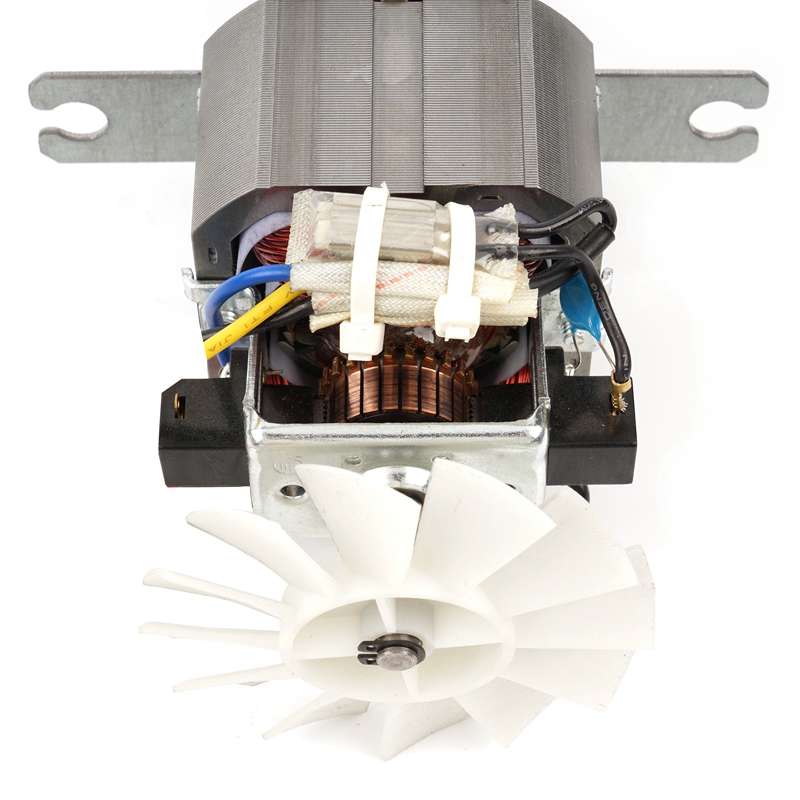

High Volume AC Motor

Our proud High Volume AC Motor is a well-designed and manufactured high-capacity AC motor. We not only provide AC motors with standard specifications, but also support customized OEM and ODM AC Motor services to meet the needs of various applications. High-capacity AC motors are known for their superior performance and durability, and are suitable for a variety of high-load working environments. Our professional team will work with you to ensure the best solution to meet your specific requirements. Whether it is a large-volume purchase or a customized AC motor, we are always committed to providing first-class products and services.

| Origin | China |

| Voltage | 220V~230V,50 Hz |

| Logo | Custom logos are accepted |

| OEM / ODM | Availalbe |

| Packaging | Custom packaging is accepted |

| Transportation | BY SEA /BY AIR/LAND CARRIAGE |

| payment Method | T/T, L/C, D/P, PAYPAL, WESTERN UNION, CREIDT CARDS |

| Terms of Trade | EXW, FOB, CNF, CIF, DOOR TO DOOR |

| Supply Capacity | 5000000 pcs annual output |

The clients’ requirements determine how OEM and ODM AC motors are made. The power output, voltage, speed, torque and size of these motors can be adjusted to achieve the best performance for different purposes.

OEM and ODM AC motors pursuit efficiency above all other things. These engines are engineered to minimize energy loss while maximising output reducing cost of operations incurred in energy usage and also saves environment pollution. Various materials and design approaches are used in order to achieve optimum efficiency levels.

OEM and ODM AC motors are built strong so that they last long even under harsh situations. The superior quality constructions together with top notch engineering ensures that they have a lengthy lifespan with good performance under tough industrial surroundings as well.

There is a wide application range for these bespoke ac motors such as: Industrial machinery, HVAC systems, Pumps, Compressors, Conveyors, Electric vehicles, Renewable energy systems like wind or solar power generation systems.,Robotics Home appliances , Agriculture , Medical equipment ,Marine applications , The food & beverage industry.

Maintenance of performance and life span is greatly enhanced by effective cooling mechanisms . Some OEMs and ODMs will use forced air cooling or liquid cooling inside their AC motor designs to ensure it doesn’t over heat hence it operates consistently.

Precision plays a major role in speed and torque control especially when it comes to some industrial applications.OEM’s as well as ODM’s AC Motors can be operated through various controllers like Variable Frequency Drives (VFDs) or servo controls for precise motor operation at low power input.

Milling machines, lathes, CNC machines, and drilling equipment are some of the industrial machinery that employs OEM and ODM AC motors to provide precise control and reliable performance which are necessary for efficient manufacturing processes and high-quality products.

Custom AC motors in heating, ventilation, and air conditioning (HVAC) systems drive fans, compressors, and pumps. This ensures optimal climate control, energy efficiency, durability in residential, commercial or industrial buildings.

Different types of pumping as well as compression applications including hydraulic pumps water pumps and air compressors among others utilize OEM/ODM AC motors with strong constructions that ensure consistency in performance while maintaining optimal pressure as well as flow rates both at home or work place.

Custom AC motors power conveyor systems and material handling equipment used for efficiently moving products through the various steps of manufacturing processes; thus their precision nature plays a big role in making sure goods under process move smoothly without breakages contributing towards productivity increment.

The automotive industry uses custom AC motors in electric vehicles for their high efficiency and torque. Through this application these EVs have drivetrains powered by DC Motors which reduce emissions hence advancing sustainable transportation solutions.

OEM-ODM ac-motors play an important role in renewable energy systems like wind turbines as well as solar power plants whereby they convert mechanical into electrical energy for instance; it applies when we talk about wind turbines or where there is mention of solar power system these assist tracking mechanisms plus other auxiliary functions thereof.

For robotic arms movement plus operation of automated machinery within robotics & automation setup calls for custom ac-motors because they offer precise control that is required while accuracy combined with responsiveness helps increase productivity as well as precision between different aspects ranging from manufacturing medical care delivery.

The advantages include optimized performance, increased efficiency, enhanced durability, precise control, and tailored features that meet the specific needs of the application. Customization leads to better integration and overall improved operational efficiency.

To specify requirements, provide detailed information about the application, including desired power output, voltage, speed, torque, size constraints, environmental conditions, and any specific features or certifications needed.

High-quality materials such as high-performance magnets, lightweight composites, durable metals, and advanced insulation materials are used. The selection of materials depends on the specific application and operational requirements.

Yes, these motors can be designed for high energy efficiency. Manufacturers use advanced design techniques and materials to minimize energy losses and maximize output, helping to reduce operational costs and environmental impact.

These motors undergo rigorous testing and quality assurance processes, including performance tests, durability tests, and safety checks. Testing may involve simulations and real-world conditions to verify performance.

These motors can be integrated with various control systems, including variable frequency drives (VFDs), servo controls, and programmable logic controllers (PLCs), providing precise control over motor speed, torque, and operation.

They can be designed to be environmentally friendly by using recyclable materials, eco-friendly manufacturing processes, and energy-efficient designs. These motors help reduce energy consumption and lower greenhouse gas emissions.