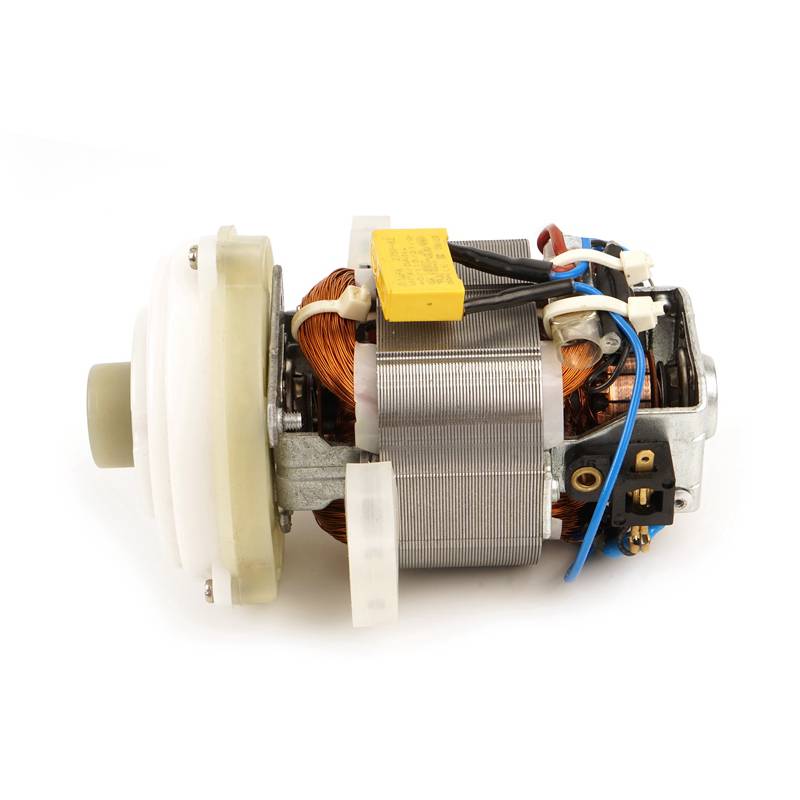

The Large AC Motor shell is made of high-strength cast iron, and the surface is specially treated. A variety of processes can be provided according to customer needs. The internal copper winding coil is a large AC Motor designed for industrial-grade loads and efficient operation. It is widely used in high-power drive fields.

Large AC Motor uses high-permeability silicon steel sheets to manufacture the rotor and stator cores to increase the magnetic flux density, and cooperates with the copper winding to improve the conductivity efficiency, so that the operation efficiency of the whole machine under rated load reaches more than 90%, greatly reducing energy consumption. It is particularly suitable for industrial scenarios with continuous operation and reduces operating costs. Under constant speed operation, the motor has low heat loss, and even if it works continuously for a long time, it will not overheat, effectively extending the life of the equipment. Its power range covers 1.5kW to 400kW, which is suitable for various medium and large equipment and meets international energy efficiency standards.

The motor structure has been professionally simulated and analyzed by finite element simulation to ensure that each key stress point is strengthened and the overall vibration value is less than 2.5mm/s. The front and rear end covers are embedded with SKF or NSK brand high-load bearings, which run smoothly and have a service life of more than 20,000 hours. The shell protection level can reach IP55, with excellent dust and water resistance, and can operate stably even in a factory environment with humidity, dust or heavy oil mist. The cooling system adopts an integrated air-cooled design, and the fan blades are made of ABS high-heat-resistant material, which can maintain good heat dissipation efficiency even after long-term high-load operation.

Large AC Motor can support multiple installation methods such as horizontal, vertical, and flange types to meet the design requirements of different mechanical structures. The motor terminal box adopts a rotatable design to facilitate cable layout. Its control interface is compatible with a variety of electronic control systems and can be seamlessly connected with a variety of industrial control equipment such as inverters, PLCs, and relays. For automation equipment customers, encoders, thermal protectors, brakes and other extended function modules can also be selected to further improve control accuracy and safety performance. The whole machine has multiple international certifications such as CE, RoHS, CB, and ETL, and is suitable for export to markets such as Europe, America, and the Middle East.

| Origin | China |

| Voltage | 220V~230V,50 Hz |

| Logo | Custom Logos Are Accepted |

| OEM / ODM | Availalbe |

| Packaging | Custom Packaging Is Accepted |

| Transportation | BY SEA /BY AIR/LAND CARRIAGE |

| Payment Method | T/T, L/C, D/P, PAYPAL, WESTERN UNION, CREIDT CARDS |

| Terms Of Trade | EXW, FOB, CNF, CIF, DOOR TO DOOR |

| Supply Capacity | 5000000 Pcs Annual Output |

In the intelligent processing workshop of Siemens in Germany, Large AC Motor is widely used in CNC lathes, injection molding machines and large conveyor belt systems. These scenarios place extremely high demands on the stability and precise control of the motor. Large AC Motor, with its excellent thermal balance and low failure rate, helps the factory achieve 24-hour efficient production. In addition, its high compatibility with the PLC system significantly shortens the equipment commissioning cycle and improves the response efficiency of the entire production line.

In the automated terminal of Jurong Port in Singapore, Large AC Motor is used in heavy container cranes and ground handling systems. Since port equipment is exposed to salt spray for a long time, the anti-corrosion protection requirements for the equipment are extremely high. Large AC Motor adopts a double-layer epoxy resin coating process and an IP55 protection grade housing. While ensuring strong power output, it effectively prevents internal electronic components from being damaged by oxidation, ensuring trouble-free operation of the handling system throughout the year.

In the mixing station of UltraTech Cement, a well-known cement manufacturer in India, Large AC Motor is used in key links such as cement powder mixers and belt conveyor lines. The model selected by the company is a 75kW vertical flange-mounted motor equipped with customized high-temperature resistant bearings, which can maintain stable speed output for a long time in dust and high temperature environments. Thanks to its excellent heat dissipation performance and simple maintenance structure, this product reduces about 10% of downtime for customers each year and significantly improves production efficiency.

In the wind power plant of Acciona, a Spanish renewable energy company, Large AC Motor is integrated into the wind energy storage equipment for wind turbine start-up control and energy allocation of energy storage battery packs. Since the wind farm is far away from the city and the temperature difference is large, the temperature adaptability and start-up response speed of the motor are very critical. After special treatment, the starting torque of this product is increased to 200%, which can quickly respond to system instructions under low voltage conditions to ensure maximum wind energy utilization efficiency.

As a leading motor manufacturing enterprise, Junhui Motor Co., Ltd. always insists on providing customers with the best quality service and products to meet their needs and expectations. We focus on creating a full range of solutions to ensure customer satisfaction and happiness, allowing customers to experience the best service and quality. We are committed to continuously improving product quality and service standards to create a more valuable choice for customers.