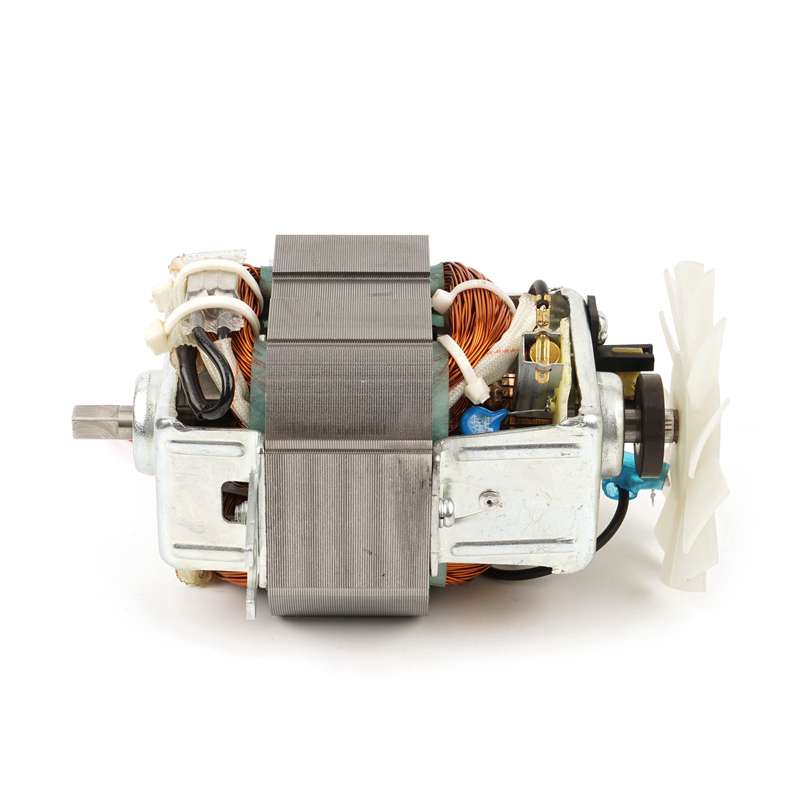

AC Brushed Motor has a cylindrical package structure, with bearing end covers at the front and back, and carbon brush components and heat dissipation channels visible in the middle. The interior is composed of core components such as winding copper wire, electromagnet, rotor coil, etc. It is compact and durable, suitable for high starting torque and frequent start-stop scenarios. It is a motor that realizes current switching based on carbon brush and commutator structure.

| Origin | China |

| Voltage | 220V~230V,50 Hz |

| Logo | Custom Logos Are Accepted |

| OEM / ODM | Availalbe |

| Packaging | Custom Packaging Is Accepted |

| Transportation | BY SEA /BY AIR/LAND CARRIAGE |

| Payment Method | T/T, L/C, D/P, PAYPAL, WESTERN UNION, CREIDT CARDS |

| Terms Of Trade | EXW, FOB, CNF, CIF, DOOR TO DOOR |

| Supply Capacity | 5000000 Pcs Annual Output |

One of the biggest advantages of AC Brushed Motor is its large initial torque output, which can provide strong driving force at the moment of motor start, which is very suitable for high-load or frequent start-stop systems, such as washing machines, grinders, etc.

AC Brushed Motor can easily control the motor speed and direction by changing the power supply voltage, without complex controllers or inverters, especially for equipment with high control flexibility requirements but limited budgets.

Compared with brushless motors, brushed structures have lower manufacturing costs and maintenance difficulties, which are suitable for mid- and low-end product lines that pursue cost-effectiveness, and are the preferred solution for many entry-level equipment or industrial products.

Although carbon brushes are consumable parts, the clear structure and replaceable design make the maintenance cycle predictable and the cost controllable, avoiding the replacement of the whole machine due to damage to high-end parts.

This type of motor has stable performance in high-load and high-current operation in a short period of time, is not prone to thermal decay, and is suitable for periodic load operation.

1. Applied to the home appliance industry - driving washing machines, blenders, and vacuum cleaners

AC Brushed Motor is widely used in traditional household appliances, especially in the drainage pump of washing machines, the main motor of vacuum cleaners, and the high-speed rotating shaft of blenders. Its high speed and fast response characteristics meet the needs of high efficiency in home scenarios.

2. Applied to industrial processing equipment - providing rotation and vibration drive

In light industrial equipment such as electric grinders, electric drills, and vibration platforms, brushed motors are the main power source. With their high power density and high cost performance, they continuously output rotational force or vibration force, making them an important choice for many machinery manufacturers.

3. Applied in sewing and textile industry - driving needle bar and bobbin system

Many traditional sewing machines and textile machines still rely on AC brush motors to complete power output. This type of motor can respond quickly to start and stop in complex mechanical structures, and is suitable for textile operations with high-frequency rhythm.

4. Applied in small medical equipment - driving pumping or rotating parts

In some small medical air pumps, centrifugal equipment or motor auxiliary devices, this motor provides basic power support, especially for short-term, repetitive workloads.

5. Applied in consumer electronics such as toys and power tools - providing precise electric drive support

AC brush motors are used in multiple consumer product lines such as electric toys, electric toothbrushes, shavers and portable power tools with their advantages of small size, light weight and fast speed.

Reliable quality, bulk supply, customized on demand

Whether you are a large home appliance brand, industrial equipment manufacturer, or cross-border trader, we can provide you with cost-effective AC brush motor solutions. We support sample application, fast proofing and customization services, welcome to negotiate!