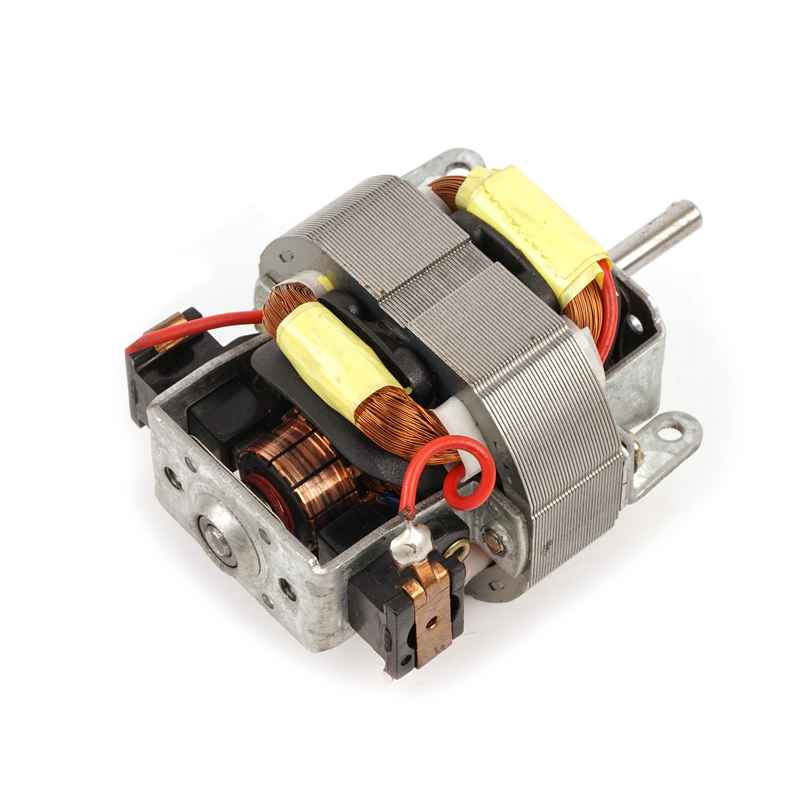

The Universal AC Motor is an extremely adaptable motor that can operate efficiently on either alternating current (AC) or direct current (DC) power. The Universal AC Motor is compact and rugged, with dual-shaft output, precision-engineered armature, and finely wound copper coils that are insulated for long life.

The Universal AC Motor operates at 220V~230V and 50Hz, and is optimized for global electrical standards. Its design accommodates both AC and DC inputs, allowing it to be exported to different regional markets without redesigning the core system.

The Universal AC Motor uses a series-excited structure that allows for extremely high speeds, making it a great choice for applications that require fast acceleration and high torque. As a result, it is ideal for tools and equipment where fast motor response is critical.

Despite its compact size, the Universal AC Motor delivers impressive output power. This is due to the precision-balanced rotor and stator, as well as the compact winding system, which saves space while maintaining mechanical strength and thermal efficiency.

Universal AC motors are easier to control speed and torque than other types of motors, especially when using variable resistors or simple electronic components. This helps reduce system complexity and costs for original equipment manufacturers (OEMs) that manufacture electric products.

Due to fewer components and a simplified structure, this motor is extremely cheap to produce and maintain. It also supports OEM/ODM customization, including shaft size, mounting brackets, and wiring options, which reduces manufacturers' integration costs.

Universal AC Motor is designed for heavy-duty use, and its commutator and brushes are made of wear-resistant materials for easy daily maintenance. Its heat insulation and vibration resistance ensure its durability in harsh environments.

| Origin | China |

| Voltage | 220V~230V,50 Hz |

| Logo | Custom Logos Are Accepted |

| OEM / ODM | Availalbe |

| Packaging | Custom Packaging Is Accepted |

| Transportation | BY SEA /BY AIR/LAND CARRIAGE |

| Payment Method | T/T, L/C, D/P, PAYPAL, WESTERN UNION, CREIDT CARDS |

| Terms Of Trade | EXW, FOB, CNF, CIF, DOOR TO DOOR |

| Supply Capacity | 5000000 Pcs Annual Output |

1. Used in the home appliance industry - Powering high-speed devices

Universal AC Motor is widely used in home appliances such as vacuum cleaners, blenders, food processors, sewing machines, and hair dryers. Its lightweight design and high-speed performance enable compact devices to provide powerful performance without increasing size or energy consumption.

2. For Power Tool Manufacturing - Achieve Precise Control of Torque and Speed

Industrial and semi-professional power tools rely on this motor type for its fast acceleration and high torque at low voltage. Manufacturers of power tools in the woodworking, construction and automotive repair industries always prefer universal motors for their high reliability and efficient energy transfer.

3. For Commercial Kitchen Equipment - Support Continuous Heavy Duty Operation

Commercial blenders, coffee grinders and dough mixers integrate universal motors to meet the performance needs of restaurants and food processing facilities. The motor's ability to operate for long periods of time under variable loads makes it ideal for continuous duty applications in the hospitality and catering industries.

4. For Personal Care Products - Ensure Lightweight and Safe Operation

Electric shavers, toothbrushes and facial cleansers benefit from the quiet, smooth and vibration-controlled operation of universal motors. The motor's slim design allows it to be installed in ergonomic housings, ensuring safety and comfort in personal care applications.

OUR MANAGEMENT

We also pay attention to the sustainable development of the enterprise and brand building, and regard actual execution as the core of enterprise management. Through strict implementation of quality management, standardized production and process optimization, we can improve enterprise management efficiency and customer satisfaction, and promote the healthy and stable development of the enterprise.

OUR FUTURE

The future goal and vision of Junhui Motor Co., Ltd. is to become an internationally leading motor manufacturing enterprise with a sense of social responsibility and good credibility. With quality, service, innovation and environmental protection as the core competitiveness, the company, customers, employees and society will achieve common development and common prosperity. We firmly believe that only by achieving a balanced development of social benefits, economic benefits and environmental benefits can an enterprise continue to develop and grow. We strive to make unremitting efforts to create a better world, so that Junhui Electric Co., Ltd. can become a brand with leading position and competitive advantage in the industry.

JUNHUI ELECTRIC MANUFACTURE CO.,LTD. is a micro motor manufacturer who dedicated to the research, development, and production of Universal motors, PMDC motors, Shaded Pole motors and related drive solutions. The products and solutions we provide are widely used in multiple areas such as home appliances, power tools, , personal care devices, commercial appliances, health care devices, and so on.

JUIHUI has been approved ISO 9001:2015 quality management system, and won the title of National High-tech Enterprise in 2021, Our universal motor, DC motor and Shaded pole motor are in line with CE and ROHS standards. And we have an experienced R&D team and quality control department to provide customers with customized and high-quality products.

JUIHUI has high level automated production lines and advanced testing equipment, annual capacity reach 5 million units. And we also produce motor hardware parts such as shaft, bracket etc, ensure products' quality and competitive prices. In addition, we also have a professional business team, to provide customers with flexible and professional services to achieve mutual benefit and win-win cooperation.

10+year experience in electric motor manufacturing

Annual Capacity: 5 million units

20+ automatic and semi-automatic production lines

300+ employees

20,000+ square meters area