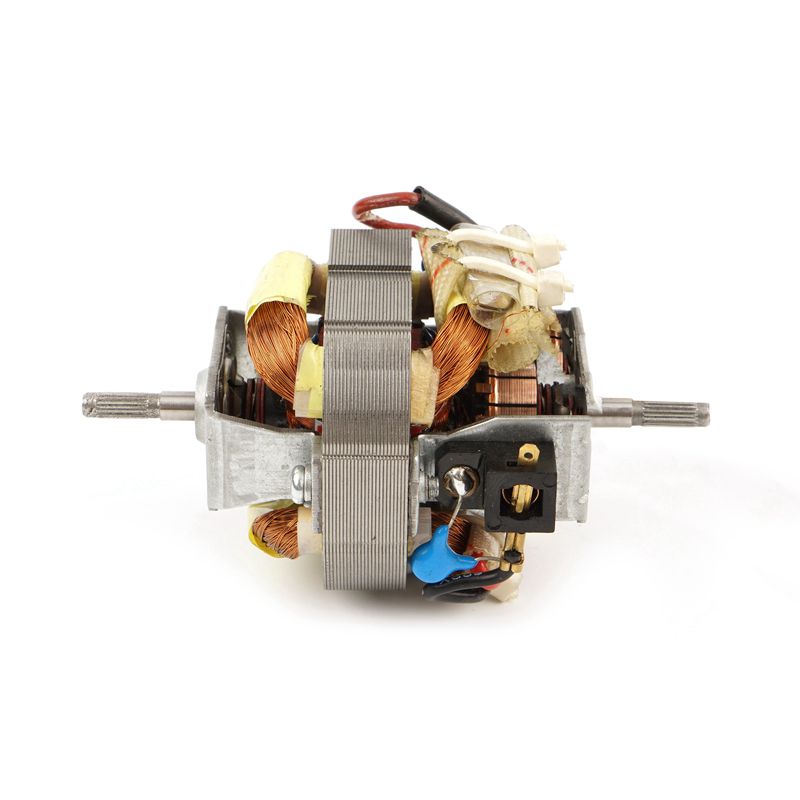

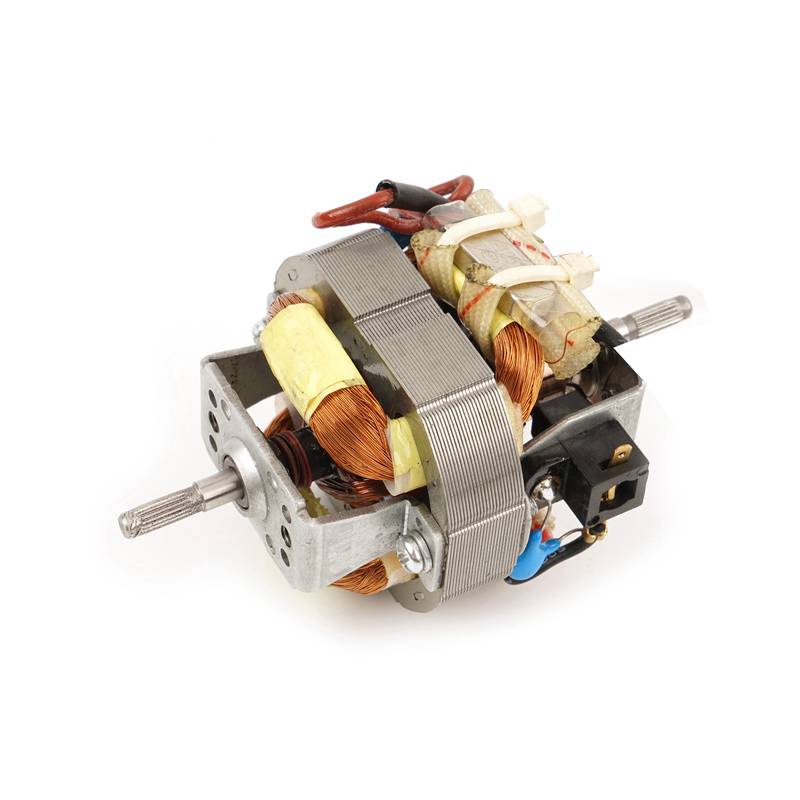

Permanent Magnet AC Synchronous Motor has a symmetrical metal structure, a dual-axis design, and coil windings are neatly and tightly distributed on both sides, with clearly visible wire ports. The body adopts a multi-layer silicon steel lamination structure, combined with copper wire coils and composite insulation materials. It is a type of motor that uses high-performance permanent magnets as the rotor magnetic source.

| Origin | China |

| Voltage | 220V~230V,50 Hz |

| Logo | Custom Logos Are Accepted |

| OEM / ODM | Availalbe |

| Packaging | Custom Packaging Is Accepted |

| Transportation | BY SEA /BY AIR/LAND CARRIAGE |

| Payment Method | T/T, L/C, D/P, PAYPAL, WESTERN UNION, CREIDT CARDS |

| Terms Of Trade | EXW, FOB, CNF, CIF, DOOR TO DOOR |

| Supply Capacity | 5000000 Pcs Annual Output |

Permanent Magnet AC Synchronous Motor uses high-performance NdFeB permanent magnet materials as the source of the magnetic field, eliminating excitation losses and significantly improving the energy efficiency ratio compared to traditional asynchronous motors. It can effectively reduce energy consumption at the same output power and is widely used in industrial and commercial equipment that is sensitive to energy costs.

Because the Permanent Magnet AC Synchronous Motor runs synchronously with the grid frequency, its speed remains constant and does not change due to load fluctuations. This feature makes it very suitable for application scenarios that require precise control of speed and torque, such as automation equipment, CNC machinery, etc., and is particularly suitable for systems that require extremely high operating stability.

Permanent Magnet AC Synchronous Motor adopts dual-bearing support structure and compact winding wiring technology to effectively reduce the overall volume and weight. It can be easily embedded and installed even in space-constrained application environments, suitable for embedded or modular system integration.

With excellent thermal stability and mechanical strength, the motor can maintain uniform temperature rise, insulation failure, and internal components are not easy to loosen or wear even in high-load operation for a long time, ensuring long-term continuous output performance without attenuation.

Permanent Magnet AC Synchronous Motor supports 220V~230V, 50Hz conventional industrial voltage range, adapts to global mainstream working conditions standards, and can customize frequency parameters and motor controller interfaces according to customer needs to meet system compatibility requirements in different countries and regions.

1. Applied to HVAC industry, it helps to improve the energy efficiency level of equipment

This permanent magnet AC synchronous motor is widely used in core components of HVAC equipment such as air-conditioning fans and compressor drives. Its high efficiency and low consumption characteristics can help the whole machine pass the European and American energy-saving certification, improve the energy efficiency label level, and enhance market competitiveness.

2. Applied in the household appliance industry, it can help achieve silent operation and extend life.

International brands such as Whirlpool and Panasonic use this type of motor as the main drive in washing machines, electric range hoods, electric water heaters and other products. Its low-noise operation and brushless structure can effectively reduce electromagnetic noise and mechanical wear, and extend the service life of the whole machine.

3. Applied in the field of industrial automation, it can help achieve high-precision closed-loop control.

In automation equipment such as CNC machine tools, automatic feeders, and robot arms, the use of permanent magnet synchronous motors can achieve high response and precise control of movement speed and torque, which can help improve product precision processing capabilities and production efficiency.

4. Applied in the power tool industry, it can help enhance power output and control stability.

This motor is commonly used in high-end electric drills, sanders, electric cutting tools, etc., and is particularly suitable for scenarios that require fast start and stop and strong output. Cooperating brands such as Bosch and Makita rely heavily on permanent magnet motors because they can ensure that power tools are light and powerful.

5. Applied to commercial kitchens and food processing machinery, it helps to optimize operational reliability

In large kitchen equipment such as blenders, juicers, and slicers, permanent magnet synchronous motors can continuously output stable torque, avoid jamming and speed jumps, and cooperate with the transmission system to improve the durability of the entire machine. They are suitable for the high-frequency catering service industry.