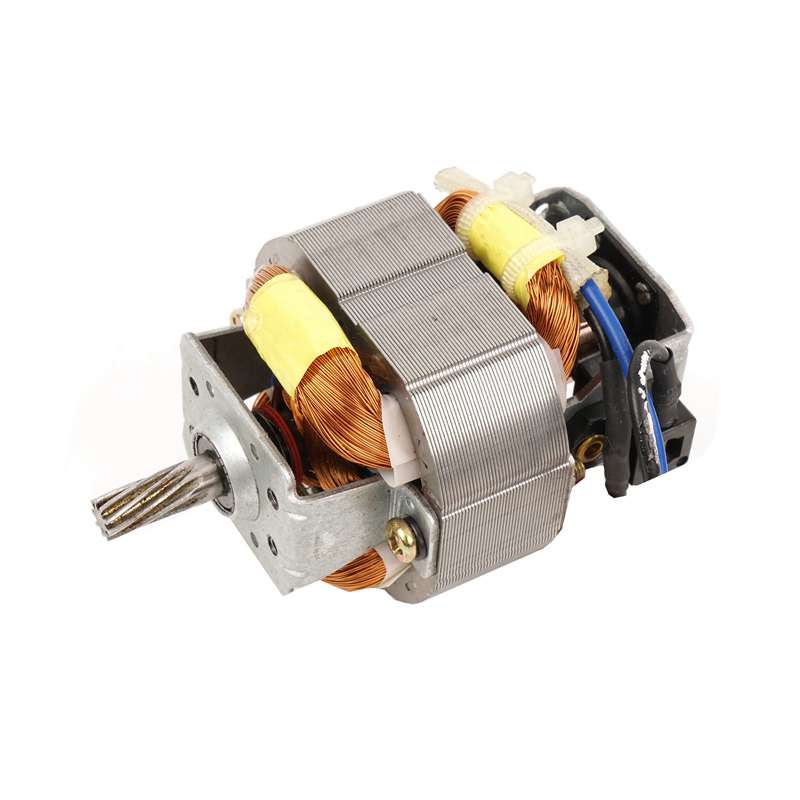

Permanent Magnet Synchronous AC Motor has a compact overall shape, a high-density aluminum alloy shell, a sealed structure for the junction box on the shell, and a motor that is compatible with a variety of flange and base installation methods. It is a high-efficiency AC Motor that uses permanent magnet material as the rotor magnetic source and is driven by a sine wave current.

| Origin | China |

| Voltage | 220V~230V,50 Hz |

| Logo | Custom Logos Are Accepted |

| OEM / ODM | Availalbe |

| Packaging | Custom Packaging Is Accepted |

| Transportation | BY SEA /BY AIR/LAND CARRIAGE |

| Payment Method | T/T, L/C, D/P, PAYPAL, WESTERN UNION, CREIDT CARDS |

| Terms Of Trade | EXW, FOB, CNF, CIF, DOOR TO DOOR |

| Supply Capacity | 5000000 Pcs Annual Output |

This motor uses NdFeB rare earth permanent magnet material, which has stable magnetic properties and high magnetic flux density. With a sine wave drive controller, it can achieve a rated energy efficiency of up to 96%, greatly reducing power loss. The typical power range is between 1.5kW and 15kW, and the rated voltage is 220V/380V. Customized voltage specifications can be provided according to project requirements. Due to the lack of excitation loss, its efficiency under light load is also higher than that of traditional asynchronous motors, effectively improving the energy saving level of the overall system.

Due to the use of high-magnetic-density permanent magnet rotors, this series of motors are smaller and lighter at the same output power. For example, a permanent magnet synchronous motor with a rated power of 5.5kW weighs about 22kg, which is only about 70% of the equivalent asynchronous motor, making it easy to install in space-constrained equipment. This feature makes it very suitable for industrial equipment that is sensitive to weight and volume, such as electric vehicles, robots, and air compressors.

By optimizing the electromagnetic structure and mechanical dynamic balance design, and matching the ball bearing and electromagnetic silent coil wiring method, the sound pressure of the motor is controlled below 45dB during operation, and there is almost no obvious mechanical noise. The torque fluctuation is less than 2%, and there is no jitter operation, which is conducive to achieving stable working conditions in high-precision applications such as CNC machine tools and medical equipment.

The permanent magnet synchronous motor supports encoder closed-loop feedback control, fast start-stop response time, and high speed regulation linearity. With the digital controller, the speed control accuracy can be achieved within ±1rpm, and the torque response time is <10ms. It is particularly suitable for application environments with extremely high dynamic performance requirements such as robot joints and automated assembly lines.

The motor structure has no mechanical contact with the brush parts, thus reducing the spark and erosion phenomenon. The internal winding uses double-layer enameled wire with H-class insulation (temperature resistance 180℃), and the sustainable working temperature can be controlled in the range of 80~100℃. The product design life is ≥30,000 hours, the maintenance interval is long, and the operation is more stable and reliable.

In the Bosch industrial assembly plant in Germany, Permanent Magnet Synchronous AC Motor is used in its automatic torque assembly equipment drive system. With its high response speed and precise angle control capability, the bolt locking error is less than ±1%, ensuring that the production efficiency and qualified rate of the entire assembly line are significantly improved.

In BYD's electric bus power system, this type of permanent magnet synchronous motor is used as the main driving power source to provide continuous high torque output. With the intelligent inverter, it can meet the needs of frequent start-stop and ramp start in urban road conditions. At the same time, it can still maintain more than 95% efficiency when running at 80% of the rated power, greatly extending the battery life.

Siemens Healthineers selected this type of permanent magnet synchronous motor in its magnetic resonance MRI rotating platform because of its low noise and zero interference electromagnetic wave characteristics, which will not affect the accuracy of the imaging system. Precision closed-loop control ensures that the speed fluctuation is less than 0.5rpm, providing extremely high stability for image acquisition.

In the high-rise commercial building project of OTIS Elevator, this motor is used in the traction drive module. Its compact design is easy to hide and install, and it also has high load starting torque and safe brake feedback interface. After linkage with the variable frequency speed regulator, it can achieve smooth start and accurate positioning of the floor station, improving the comfort and safety of the elevator.

Denmark's Vestas Wind Power System has configured this permanent magnet synchronous motor in the yaw control system of its 1.5MW wind turbine. With its high torque density, it can still provide sufficient torque at low speed and low pressure, ensuring the steering accuracy of the wind turbine and extending the service life of the yaw mechanism.